Suppliers of Disc springs

This product is regulated by the following standards:

Technical data

Disc springs

This product is regulated by the following standards:

Standard UNI 8737

Disc springs

|

Dimensions in mm - UNI 8737 - Withdrawn Publication date: 11-1985 |

|||||||||

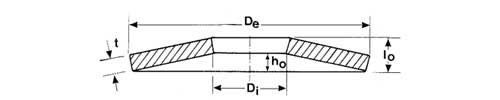

| De | Di | t | lo | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | |||||

| 8 | 4.2 | 0.2 | 0.45 | 0.05 | |||||

| 8 | 4.2 | 0.3 | 0.55 | 0.07 | |||||

| 8 | 4.2 | 0.4 | 0.6 | 0.1 | |||||

| 10 | 5.2 | 0.25 | 0.55 | 0.1 | |||||

| 10 | 5.2 | 0.4 | 0.7 | 0.16 | |||||

| 10 | 5.2 | 0.5 | 0.75 | 0.21 | |||||

| 12.5 | 6.2 | 0.35 | 0.8 | 0.23 | |||||

| 12.5 | 6.2 | 0.5 | 0.85 | 0.34 | |||||

| 12.5 | 6.2 | 0.7 | 1 | 0.47 | |||||

| 14 | 7.2 | 0.35 | 0.8 | 0.29 | |||||

| 14 | 7.2 | 0.5 | 0.9 | 0.42 | |||||

| 14 | 7.2 | 0.8 | 1.1 | 0.66 | |||||

| 16 | 8.2 | 0.4 | 0.9 | 0.44 | |||||

| 16 | 8.2 | 0.6 | 1.05 | 0.66 | |||||

| 16 | 8.2 | 0.9 | 1.25 | 0.99 | |||||

| 18 | 9.2 | 0.45 | 1.05 | 0.63 | |||||

| 18 | 9.2 | 0.7 | 1.2 | 0.98 | |||||

| 18 | 9.2 | 1 | 1.4 | 1.4 | |||||

| 20 | 10.2 | 0.5 | 1.15 | 0.87 | |||||

| 20 | 10.2 | 0.8 | 1.35 | 1.38 | |||||

| 20 | 10.2 | 1.1 | 1.55 | 1.91 | |||||

| 22.5 | 11.2 | 0.6 | 1.4 | 1.35 | |||||

| 22.5 | 11.2 | 0.8 | 1.45 | 1.79 | |||||

| 22.5 | 11.2 | 1.25 | 1.75 | 2.81 | |||||

| 25 | 12.2 | 0.7 | 1.6 | 1.96 | |||||

| 25 | 12.2 | 0.9 | 1.6 | 2.53 | |||||

| 25 | 12.2 | 1.5 | 2.05 | 4.24 | |||||

| 28 | 14.2 | 0.8 | 1.8 | 2.75 | |||||

| 28 | 14.2 | 1 | 1.8 | 3.45 | |||||

| 28 | 14.2 | 1.5 | 2.15 | 5.2 | |||||

| 31.5 | 16.3 | 0.8 | 1.85 | 3.4 | |||||

| 31.5 | 16.3 | 1.25 | 2.15 | 5.4 | |||||

| 31.5 | 16.3 | 1.75 | 2.45 | 7.6 | |||||

Standard DIN 2093

Disc springs

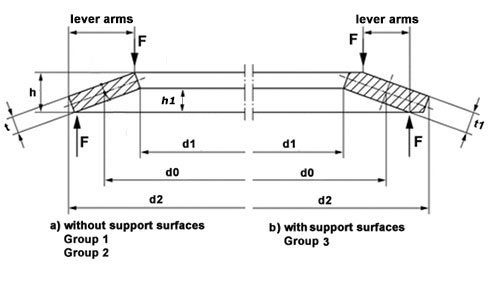

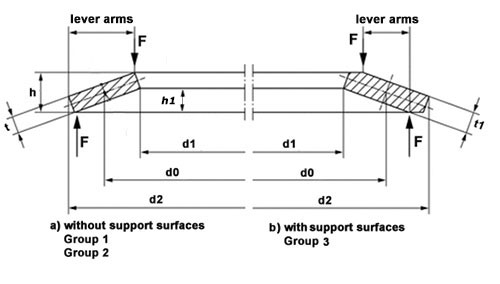

This standard (DIN 2093) specifies the requirements disc springs need to have in order to guaratee their functions, such as equirements on material, type of production, measure and strength tolerances, requirements for durability and time as well as relaxation values at statistic use. Disc springs are conically-shaped, washer-type parts designed to be axially loaded. The deflection for a given load is predictable and the minimum life cycle can be determined. They can be used singly or in multiples stacked parallel. Disc springs can statically loaded either continuosly or intermittently, or dynamically subjected to continuos load cycling. They are produced as per DIN 2093 and designed as per DIN 2092.

|

Dimensions in mm - DIN 2093 - Withdrawn Publication date: 12/2013 - Supersedes DIN 2093 01/1992;

The DIN 2093 specification classifies disc springs into 3 groups: GROUP 1: under 1.25 mm thick (cold formed,radiused edges, without bearing flats) GROUP 2: 1.25 mm thick up to and including 6mm (cold formed,machined,radiused edges, without bearing flats) GROUP 3: above 6mm thick (fully machined from forged blanks, with bearing flats and thickness reduced) |

||||||||||||

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| - | 6 | 3.2 | 0.3 | 0.15 | 0.45 | - | 45 | 84 | 119 | 153 | 0.044 | |

| C | 8 | 4.2 | 0.2 | 0.25 | 0.45 | 21 | 33 | 39 | 42 | 0.055 | ||

| B | 8 | 4.2 | 0.3 | 0.25 | 0.55 | 1 | 52 | 89 | 118 | 142 | 0.08 | |

| A | 8 | 4.2 | 0.4 | 0.2 | 0.6 | 1 | 78 | 147 | 210 | 269 | 0.115 | |

| C | 10 | 5.2 | 0.25 | 0.3 | 0.55 | 1 | 30 | 48 | 58 | 63 | 0.109 | |

| B | 10 | 5.2 | 0.4 | 0.3 | 0.7 | 1 | 88 | 155 | 209 | 257 | 0.161 | |

| A | 10 | 5.2 | 0.5 | 0.25 | 0.75 | 1 | 122 | 228 | 325 | 418 | 0.209 | |

| C | 12.5 | 6.2 | 0.35 | 0.45 | 0.8 | 1 | 84 | 130 | 151 | 160 | 0.251 | |

| B | 12.5 | 6.2 | 0.5 | 0.35 | 0.85 | 1 | 120 | 215 | 293 | 363 | 0.251 | |

| A | 12.5 | 6.2 | 0.7 | 0.3 | 1 | 1 | 239 | 457 | 660 | 855 | 0.483 | |

| C | 14 | 7.2 | 0.35 | 0.45 | 0.8 | 1 | 68 | 106 | 123 | 131 | 0.308 | |

| B | 14 | 7.2 | 0.5 | 0.4 | 0.9 | 1 | 120 | 210 | 279 | 338 | 0.308 | |

| A | 14 | 7.2 | 0.8 | 0.3 | 1.1 | 1 | 284 | 547 | 797 | 1040 | 0.654 | |

| C | 16 | 8.2 | 0.4 | 0.55 | 0.9 | 1 | 84 | 131 | 154 | 165 | 0.444 | |

| B | 16 | 8.2 | 0.6 | 0.45 | 1.05 | 1 | 172 | 304 | 410 | 503 | 0.656 | |

| A | 16 | 8.2 | 0.9 | 0.45 | 1.25 | 1 | 363 | 697 | 1010 | 1320 | 0.994 | |

| C | 18 | 9.2 | 0.45 | 0.65 | 1.05 | 1 | 121 | 186 | 214 | 223 | 0.651 | |

| B | 18 | 9.2 | 0.7 | 0.6 | 1.2 | 1 | 233 | 417 | 586 | 699 | 1.05 | |

| A | 18 | 9.2 | 1 | 0.4 | 1.4 | 1 | 451 | 865 | 1250 | 1630 | 0.444 | |

| C | 20 | 10.2 | 0.5 | 0.65 | 1.15 | 1 | 141 | 219 | 254 | 268 | 0.876 | |

| B | 20 | 10.2 |

0.8 |

0.65 | 1.35 | 1 | 304 | 547 | 748 | 929 | 1.371 | |

| A | 20 | 10.2 | 1.1 |

0.45 |

1.55 | 1 | 548 | 1050 | 1520 | 1980 | 1.912 | |

| C | 22.5 | 11.2 | 0.6 | 0.8 | 1.4 | 1 | 240 | 370 | 425 | 444 | 1.361 | |

| B | 22.5 | 11.2 | 0.8 | 0.65 | 1.45 | 1 | 306 | 533 | 707 | 855 | 1.77 | |

| A | 22.5 | 11.2 | 1.25 | 0.5 | 1.75 | 1 | 693 |

1330 |

1930 | 2510 | 2.775 | |

| C | 25 | 12.2 | 0.7 | 0.9 | 1.6 | 1 | 331 | 515 | 600 | 635 | 1.984 | |

| B | 25 | 12.2 | 0.9 | 0.8 | 1.6 | 1 | 367 | 644 | 862 | 1050 | 2.5 | |

| A | 25 | 12.2 | 1.5 | 0.55 | 2.05 | 1 | 1040 | 2010 | 2930 | 3820 | 4.162 | |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| C | 28 | 14.2 | 0.8 | 1 | 1.8 | 1 | 435 | 681 | 801 | 859 | 2.76 | |

| B | 28 | 14.2 | 1 | 0.9 | 1.8 | 1 | 476 | 832 | 1110 | 1340 | 3.396 | |

| A | 28 | 14.2 | 1.5 | 0.65 | 2.15 | 2 | 1030 | 1970 | 2840 | 3680 | 5.107 | |

| C | 31.5 | 16.3 | 0.8 | 1.05 | 1.85 | 1 | 384 | 594 | 687 | 722 | 3.442 | |

| B | 31.5 | 16.3 | 1.25 | 1.15 | 2.15 | 2 | 791 | 1410 | 1910 | 2360 | 5.331 | |

| A | 31.5 | 16.3 | 1.75 | 0.7 | 2.45 | 2 | 1390 | 2670 | 3870 | 5040 | 7.493 | |

| C | 35.5 | 18.3 | 0.9 | 1.15 | 2.05 | 1 | 458 | 712 | 832 | 884 | 4.592 | |

| B | 35.5 | 18.3 | 1.25 | 1 | 2.25 | 2 | 731 | 1280 | 1700 | 2060 | 6.78 | |

| A | 35.5 | 18.3 | 2 | 0.8 | 2.8 | 2 | 1860 | 3580 | 5190 | 6750 | 11.03 | |

| C | 40 | 20.4 | 1 | 1.3 | 2.3 | 1 | 565 | 876 | 1020 | 1070 | 7.067 | |

| B | 40 | 20.4 | 1.5 | 1.4 | 2.65 | 2 | 1110 | 1950 | 2620 | 3290 | 10.392 | |

| A | 40 | 20.4 | 2.25 | 0.9 | 3.15 | 2 | 2340 | 4480 | 6500 | 8460 | 15.26 | |

| C | 45 | 22.4 | 1.25 | 1.6 | 2.85 | 2 | 1040 | 1620 | 1890 | 2100 | 15.95 | |

| B | 45 | 22.4 | 1.75 | 1.55 | 3.05 | 2 | 1520 | 2700 | 3650 | 4480 | 15.95 | |

| A | 45 | 22.4 | 2.5 | 1 | 3.5 | 2 | 2770 | 5320 | 7720 | 10000 | 22.313 | |

| C | 50 | 25.4 | 1.25 | 1.6 | 2.85 | 2 | 854 | 1330 | 1550 | 1650 | 13.82 | |

| B | 50 | 25.4 | 2 | 1.65 | 3.4 | 2 | 1950 | 3490 | 4760 | 5900 | 21.885 | |

| A | 50 | 25.4 | 3 | 1.1 | 4.1 | 2 | 4250 | 8210 | 12000 | 15600 | 32.529 | |

| C | 56 | 28.5 | 1.5 | 1.95 | 3.45 | 2 | 1460 | 2260 | 2620 | 2770 | 20.85 | |

| B | 56 | 28.5 | 2 | 1.6 | 3.6 | 2 | 1910 | 3340 | 4440 | 5380 | 27.63 | |

| A | 56 | 28.5 | 3 | 1.3 | 4.3 | 2 | 4140 | 7900 | 11400 | 14800 | 41.37 | |

| C | 63 | 31 | 1.8 | 2.35 | 4.15 | 2 | 2360 | 3660 | 4240 | 4460 | 32.53 | |

| B | 63 | 31 | 2.5 | 2.25 | 4.25 | 2 | 2940 | 5270 | 7190 | 8900 | 44.7 | |

| A | 63 | 31 | 3.5 | 1.4 | 4.9 | 2 | 5400 | 10400 | 15000 | 19500 | 62.99 | |

| C | 71 | 36 | 1 | 2.8 | 4.6 | 2 | 2860 | 4430 | 5140 | 5430 | 46.18 | |

| B | 71 | 36 | 2.5 | 2 | 4.5 | 2 | 2890 | 5050 | 6730 | 8150 | 57.72 | |

| A | 71 | 36 | 4 | 1.6 | 5.6 | 2 | 7380 | 14200 | 20500 | 26700 | 92.36 | |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| C | 80 | 41 | 2.25 | 2.95 | 5.2 | 2 | 3698 | 5715 | 6613 | 6950 | 65.460 | |

| B | 80 | 41 | 3 | 2.8 | 5.3 | 2 | 4450 | 7840 | 10500 | 12800 | 87.281 | |

| A | 80 | 41 | 5 | 1.7 | 6.7 | 2 | 11800 | 22900 | 33600 | 44000 | 145.468 | |

| C | 90 | 46 | 2.5 | 3.2 | 5.7 | 2 | 4230 | 6580 | 7680 | 8160 | 92.231 | |

| B | 90 | 46 | 3.5 | 3 | 6 | 2 | 5840 | 10400 | 14200 | 17500 | 129.124 | |

| A | 90 | 46 | 5 | 2 | 7 | 2 | 11000 | 21600 | 31400 | 40800 | 184.463 | |

| C | 100 | 51 | 2.7 | 3.5 | 6.2 | 2 | 4780 | 7410 | 8610 | 9090 | 123.164 | |

| B | 100 | 51 | 3.5 | 2.8 | 6.3 | 2 | 5620 | 9820 | 13100 | 15800 | 159.657 | |

| A | 100 | 51 | 6 | 2.2 | 8.2 | 2 | 17100 | 32900 | 48000 | 62700 | 273.698 | |

| C | 112 | 57 | 3 | 3.9 | 6.9 | 2 | 5830 | 9040 | 10500 | 11100 | 171.917 | |

| B | 112 | 57 | 4 | 3.2 | 7.2 | 2 | 7640 | 13300 | 17800 | 21500 | 229.222 | |

| A | 112 | 57 | 6 | 2.5 | 8.5 | 2 | 15800 | 30200 | 43700 | 56700 | 343.833 | |

| C | 125 | 64 | 3.5 | 4.5 | 8 | 2 | 8510 | 13200 | 15400 | 16300 | 248.775 | |

| B | 125 | 64 | 5 | 3.5 | 8.5 | 2 | 12200 | 21900 | 29900 | 37000 | 426.471 | |

| A | 125 | 64 | 8 | 2.6 | 10.6 | 3 | 30100 | 58600 | 85900 | 113000 | 529.900 | |

| C | 140 | 72 | 3.8 | 4.9 | 8.7 | 2 | 9510 | 14800 | 17200 | 18200 | 337.734 | |

| B | 140 | 72 | 5 | 4 | 9 | 2 | 12000 | 21000 | 27900 | 39800 | 444.388 | |

| A | 140 | 72 | 8 | 3.2 | 11.2 | 3 | 30600 | 58800 | 85300 | 110000 | 666.581 | |

| C | 160 | 82 | 4.3 | 5.6 | 9.9 | 2 | 12200 | 18800 | 21800 | 23000 | 500.409 | |

| B | 160 | 82 | 6 | 4.5 | 10.5 | 2 | 17200 | 30400 | 41000 | 50300 | 651.70 | |

| A | 160 | 82 | 10 | 3.5 | 13.5 | 3 | 48900 | 94600 | 138000 | 181000 | 1094.00 | |

| C | 180 | 92 | 4.8 | 6.2 | 11 | 2 | 14600 | 22700 | 26400 | 28000 | 708.337 | |

| B | 180 | 92 | 6 | 5.1 | 11.1 | 2 | 16600 | 28600 | 37500 | 44900 | 826.39 | |

| A | 180 | 92 | 10 | 4 | 14 | 3 | 45100 | 86500 | 125000 | 163000 | 1387.00 | |

| C | 200 | 102 | 5.5 | 7 | 12.5 | 2 | 19800 | 30900 | 36100 | 38400 | 1004.00 | |

| B | 200 | 102 | 8 | 5.6 | 13.6 | 3 | 31300 | 56000 | 76400 | 94600 | 1368.00 | |

| A | 200 | 102 | 12 | 4.2 | 16.2 | 3 | 64700 | 125000 | 183000 | 239000 | 2053.00 | |

| C | 225 | 112 | 6.5 | 7.1 | 13.6 | 3 | 22300 | 36300 | 44600 | 50100 | 1455.00 | |

| B | 225 | 112 | 8 | 6.5 | 14.5 | 3 | 30600 | 53300 | 70700 | 85500 | 1761.00 | |

| A | 225 | 112 | 12 | 5 | 17 | 3 | 61800 | 118000 | 171000 | 222000 | 2641.00 | |

| C | 250 | 127 | 7 | 7.8 | 14.8 | 3 | 25600 | 41300 | 50500 | 56400 | 1915.00 | |

| B | 250 | 127 | 10 | 7 | 17 | 3 | 48700 | 87300 | 119000 | 147000 | 2687.00 | |

| A | 250 | 127 | 14 | 5.6 | 19.6 | 3 | 89400 | 172000 | 249000 | 324000 | 3745.00 | |

Standard DIN EN 16983

Disc springs

|

Dimensions in mm - DIN EN 16983 Publication date: 09/2017

The DIN EN 16983 specification classifies disc springs into 3 groups: GROUP 1: under 1.25 mm thick (cold formed,radiused edges, iwthout bearing flats) GROUP 2: 1.25 mm thickup to and including 6mm (cold formed,machined,radiused edges, iwthout bearing flats) GROUP 3: above 6mm thick (fully machined from forged blanks, with bearing flats and thickness reduced) |

|||||||

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| - | 6 | 3.2 | 0.3 | - | 0.15 | 0.45 | - |

| C | 8 | 4.2 | 0.2 | - | 0.25 | 0.45 | |

| B | 8 | 4.2 | 0.3 | - | 0.25 | 0.55 | 1 |

| A | 8 | 4.2 | 0.4 | - | 0.2 | 0.6 | 1 |

| C | 10 | 5.2 | 0.25 | - | 0.3 | 0.55 | 1 |

| B | 10 | 5.2 | 0.4 | - | 0.3 | 0.7 | 1 |

| A | 10 | 5.2 | 0.5 | - | 0.25 | 0.75 | 1 |

| C | 12.5 | 6.2 | 0.35 | - | 0.45 | 0.8 | 1 |

| B | 12.5 | 6.2 | 0.5 | - | 0.35 | 0.85 | 1 |

| A | 12.5 | 6.2 | 0.7 | - | 0.3 | 1 | 1 |

| C | 14 | 7.2 | 0.35 | - | 0.45 | 0.8 | 1 |

| B | 14 | 7.2 | 0.5 | - | 0.4 | 0.9 | 1 |

| A | 14 | 7.2 | 0.8 | - | 0.3 | 1.1 | 1 |

| C | 16 | 8.2 | 0.4 | - | 0.55 | 0.9 | 1 |

| B | 16 | 8.2 | 0.6 | - | 0.45 | 1.05 | 1 |

| A | 16 | 8.2 | 0.9 | - | 0.45 | 1.25 | 1 |

| C | 18 | 9.2 | 0.45 | - | 0.65 | 1.05 | 1 |

| B | 18 | 9.2 | 0.7 | - | 0.6 | 1.2 | 1 |

| A | 18 | 9.2 | 1 | - | 0.4 | 1.4 | 1 |

| C | 20 | 10.2 | 0.5 | - | 0.65 | 1.15 | 1 |

| B | 20 | 10.2 |

0.8 |

- | 0.65 | 1.35 | 1 |

| A | 20 | 10.2 | 1.1 | - |

0.45 |

1.55 | 1 |

| C | 22.5 | 11.2 | 0.6 | - | 0.8 | 1.4 | 1 |

| B | 22.5 | 11.2 | 0.8 | - | 0.65 | 1.45 | 1 |

| A | 22.5 | 11.2 | 1.25 | - | 0.5 | 1.75 | 1 |

| C | 25 | 12.2 | 0.7 | - | 0.9 | 1.6 | 1 |

| B | 25 | 12.2 | 0.9 | - | 0.8 | 1.6 | 1 |

| A | 25 | 12.2 | 1.5 | - | 0.55 | 2.05 | 1 |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| C | 28 | 14.2 | 0.8 | - | 1 | 1.8 | 1 |

| B | 28 | 14.2 | 1 | - | 0.9 | 1.8 | 1 |

| A | 28 | 14.2 | 1.5 | - | 0.65 | 2.15 | 2 |

| C | 31.5 | 16.3 | 0.8 | - | 1.05 | 1.85 | 1 |

| B | 31.5 | 16.3 | 1.25 | - | 1.15 | 2.15 | 2 |

| A | 31.5 | 16.3 | 1.75 | - | 0.7 | 2.45 | 2 |

| C | 35.5 | 18.3 | 0.9 | - | 1.15 | 2.05 | 1 |

| B | 35.5 | 18.3 | 1.25 | - | 1 | 2.25 | 2 |

| A | 35.5 | 18.3 | 2 | - | 0.8 | 2.8 | 2 |

| C | 40 | 20.4 | 1 | - | 1.3 | 2.3 | 1 |

| B | 40 | 20.4 | 1.5 | - | 1.4 | 2.65 | 2 |

| A | 40 | 20.4 | 2.25 | - | 0.9 | 3.15 | 2 |

| C | 45 | 22.4 | 1.25 | - | 1.6 | 2.85 | 2 |

| B | 45 | 22.4 | 1.75 | - | 1.55 | 3.05 | 2 |

| A | 45 | 22.4 | 2.5 | - | 1 | 3.5 | 2 |

| C | 50 | 25.4 | 1.25 | - | 1.6 | 2.85 | 2 |

| B | 50 | 25.4 | 2 | - | 1.65 | 3.4 | 2 |

| A | 50 | 25.4 | 3 | - | 1.1 | 4.1 | 2 |

| C | 56 | 28.5 | 1.5 | - | 1.95 | 3.45 | 2 |

| B | 56 | 28.5 | 2 | - | 1.6 | 3.6 | 2 |

| A | 56 | 28.5 | 3 | - | 1.3 | 4.3 | 2 |

| C | 63 | 31 | 1.8 | - | 2.35 | 4.15 | 2 |

| B | 63 | 31 | 2.5 | - | 2.25 | 4.25 | 2 |

| A | 63 | 31 | 3.5 | - | 1.4 | 4.9 | 2 |

| C | 71 | 36 | 1 | - | 2.8 | 4.6 | 2 |

| B | 71 | 36 | 2.5 | - | 2 | 4.5 | 2 |

| A | 71 | 36 | 4 | - | 1.6 | 5.6 | 2 |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| C | 80 | 41 | 2.25 | - | 2.95 | 5.2 | 2 |

| B | 80 | 41 | 3 | - | 2.8 | 5.3 | 2 |

| A | 80 | 41 | 5 | - | 1.7 | 6.7 | 2 |

| C | 90 | 46 | 2.5 | - | 3.2 | 5.7 | 2 |

| B | 90 | 46 | 3.5 | - | 3 | 6 | 2 |

| A | 90 | 46 | 5 | - | 2 | 7 | 2 |

| C | 100 | 51 | 2.7 | - | 3.5 | 6.2 | 2 |

| B | 100 | 51 | 3.5 | - | 2.8 | 6.3 | 2 |

| A | 100 | 51 | 6 | - | 2.2 | 8.2 | 2 |

| C | 112 | 57 | 3 | - | 3.9 | 6.9 | 2 |

| B | 112 | 57 | 4 | - | 3.2 | 7.2 | 2 |

| A | 112 | 57 | 6 | - | 2.5 | 8.5 | 2 |

| C | 125 | 64 | 3.5 | - | 4.5 | 8 | 2 |

| B | 125 | 64 | 5 | - | 3.5 | 8.5 | 2 |

| A | 125 | 64 | 8 | 7.5 | 2.6 | 10.6 | 3 |

| C | 140 | 72 | 3.8 | - | 4.9 | 8.7 | 2 |

| B | 140 | 72 | 5 | - | 4 | 9 | 2 |

| A | 140 | 72 | 8 | 7.5 | 3.2 | 11.2 | 3 |

| C | 160 | 82 | 4.3 | - | 5.6 | 9.9 | 2 |

| B | 160 | 82 | 6 | - | 4.5 | 10.5 | 2 |

| A | 160 | 82 | 10 | 9.4 | 3.5 | 13.5 | 3 |

| C | 180 | 92 | 4.8 | - | 6.2 | 11 | 2 |

| B | 180 | 92 | 6 | - | 5.1 | 11.1 | 2 |

| A | 180 | 92 | 10 | 9.4 | 4 | 14 | 3 |

| C | 200 | 102 | 5.5 | - | 7 | 12.5 | 2 |

| B | 200 | 102 | 8 | 7.5 | 5.6 | 13.6 | 3 |

| A | 200 | 102 | 12 | 11.25 | 4.2 | 16.2 | 3 |

| C | 225 | 112 | 6.5 | 6.2 | 7.1 | 13.6 | 3 |

| B | 225 | 112 | 8 | 7.5 | 6.5 | 14.5 | 3 |

| A | 225 | 112 | 12 | 11.25 | 5 | 17 | 3 |

| C | 250 | 127 | 7 | 6.7 | 7.8 | 14.8 | 3 |

| B | 250 | 127 | 10 | 9.4 | 7 | 17 | 3 |

| A | 250 | 127 | 14 | 13.1 | 5.6 | 19.6 | 3 |

Standard UNI 8736

Standard DIN EN 16984

Disc springs - Calculation

Details

Disc springs

|

Dimensions in mm - DIN 2093 - Withdrawn Material: spring steel Publication date: 12/2013 - Supersedes DIN 2093 01/1992 |

|||||||||||||||

| De h12 | Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 6 | 3.2 | 0.3 | 0.15 | 0.45 | 45 | 84 | 119 | 153 | 0.044 | ||||||

| 8 | 4.2 | 0.4 | 0.2 | 0.6 | 78 | 147 | 210 | 269 | 0.115 | ||||||

| 8 | 4.2 | 0.3 | 0.25 | 0.55 | 52 | 89 | 118 | 142 | 0.08 | ||||||

| 8 | 4.2 | 0.2 | 0.25 | 0.45 | 21 | 33 | 39 | 42 | 0.055 | ||||||

| 10 | 5.2 | 0.5 | 0.25 | 0.75 | 122 | 228 | 325 | 418 | 0.209 | ||||||

| 10 | 5.2 | 0.4 | 0.3 | 0.7 | 88 | 155 | 209 | 257 | 0.161 | ||||||

| 10 | 5.2 | 0.25 | 0.3 | 0.55 | 30 | 48 | 58 | 63 | 0.109 | ||||||

| 12.5 | 6.2 | 0.7 | 0.3 | 1 | 239 | 457 | 660 | 855 | 0.483 | ||||||

| 12.5 | 6.2 | 0.5 | 0.35 | 0.85 | 120 | 215 | 293 | 363 | 0.251 | ||||||

| 12.5 | 6.2 | 0.35 | 0.45 | 0.8 | 84 | 130 | 151 | 160 | 0.251 | ||||||

| 14 | 7.2 | 0.8 | 0.3 | 1.1 | 284 | 547 | 797 | 1040 | 0.654 | ||||||

| 14 | 7.2 | 0.5 | 0.4 | 0.9 | 120 | 210 | 279 | 338 | 0.308 | ||||||

| 14 | 7.2 | 0.35 | 0.45 | 0.8 | 68 | 106 | 123 | 131 | 0.308 | ||||||

| 16 | 8.2 | 0.8 | 0.35 | 1.25 | 363 | 697 | 1010 | 1320 | 0.994 | ||||||

| 16 | 8.2 | 0.6 | 0.45 | 1.05 | 172 | 304 | 410 | 503 | 0.656 | ||||||

| 16 | 8.2 | 0.35 | 0.4 | 0.9 | 84 | 131 | 154 | 165 | 0.444 | ||||||

| 18 | 9.2 | 1 | 0.4 | 1.4 | 451 | 865 | 1250 | 1630 | 0.444 | ||||||

| 18 | 9.2 | 0.6 | 1.2 | 1.2 | 233 | 417 | 586 | 699 | 1.05 | ||||||

| 18 | 9.2 | 0.4 | 1.05 | 1.05 | 121 | 186 | 214 | 223 | 0.651 | ||||||

| 20 | 10.2 | 1.1 |

0.45 |

1.55 | 548 | 1050 | 1520 | 1980 | 1.912 | ||||||

| 20 | 10.2 | 0.7 | 1.35 | 1.35 | 304 | 547 | 748 | 929 | 1.371 | ||||||

| 20 | 10.2 | 0.5 | 1.15 | 1.15 | 141 | 219 | 254 | 268 | 0.876 | ||||||

| 22.5 | 11.2 | 1.25 | 1.75 | 1.75 | 693 |

1330 |

1930 | 2510 | 2.775 | ||||||

| 22.5 | 11.2 | 0.8 | 1.45 | 1.45 | 306 | 533 | 707 | 855 | 1.77 | ||||||

| 22.5 | 11.2 | 0.6 | 1.4 | 1.4 | 240 | 370 | 425 | 444 | 1.361 | ||||||

| 25 | 12.2 | 1.5 | 2.05 | 2.05 | 1040 | 2010 | 2930 | 3820 | 4.162 | ||||||

| 25 | 12.2 | 0.8 | 1.6 | 1.6 | 367 | 644 | 862 | 1050 | 2.5 | ||||||

| 25 | 12.2 | 0.7 | 1.6 | 1.6 | 331 | 515 | 600 | 635 | 1.984 | ||||||

| De h12 | Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 28 | 14.2 | 1.5 | 0.65 | 2.15 | 1030 | 1970 | 2840 | 3680 | 5.107 | ||||||

| 28 | 14.2 | 0.9 | 0.8 | 1.8 | 476 | 832 | 1110 | 1340 | 3.396 | ||||||

| 28 | 14.2 | 0.8 | 1 | 1.8 | 435 | 681 | 801 | 859 | 2.76 | ||||||

| 31.5 | 16.3 | 1.75 | 0.7 | 2.45 | 1390 | 2670 | 3870 | 5040 | 7.493 | ||||||

| 31.5 | 16.3 | 1 | 0.9 | 2.15 | 791 | 1410 | 1910 | 2360 | 5.331 | ||||||

| 31.5 | 16.3 | 0.8 | 1.05 | 1.85 | 384 | 594 | 687 | 722 | 3.442 | ||||||

| 35.5 | 18.3 | 2 | 0.8 | 2.8 | 1860 | 3580 | 5190 | 6750 | 11.03 | ||||||

| 35.5 | 18.3 | 1.25 | 1 | 2.25 | 731 | 1280 | 1700 | 2060 | 6.78 | ||||||

| 35.5 | 18.3 | 0.9 | 1.15 | 2.05 | 458 | 712 | 832 | 884 | 4.592 | ||||||

| 40 | 20.4 | 2.25 | 0.9 | 3.15 | 2340 | 4480 | 6500 | 8460 | 15.26 | ||||||

| 40 | 20.4 | 1.25 | 1.15 | 2.65 | 1110 | 1950 | 2620 | 3290 | 10.392 | ||||||

| 40 | 20.4 | 1 | 1.3 | 2.3 | 565 | 876 | 1020 | 1070 | 7.067 | ||||||

| 45 | 22.4 | 2.5 | 1 | 3.5 | 2770 | 5320 | 7720 | 10000 | 22.313 | ||||||

| 45 | 22.4 | 1.5 | 1.3 | 3.05 | 1520 | 2700 | 3650 | 4480 | 15.95 | ||||||

| 45 | 22.4 | 1.25 | 1.6 | 2.85 | 1040 | 1620 | 1890 | 2100 | 15.95 | ||||||

| 50 | 25.4 | 3 | 1.1 | 4.1 | 4250 | 8210 | 12000 | 15600 | 32.529 | ||||||

| 50 | 25.4 | 1.75 | 1.4 | 3.4 | 1950 | 3490 | 4760 | 5900 | 21.885 | ||||||

| 50 | 25.4 | 1.25 | 1.6 | 2.85 | 854 | 1330 | 1550 | 1650 | 13.82 | ||||||

| 56 | 28.5 | 3 | 1.3 | 4.3 | 4140 | 7900 | 11400 | 14800 | 41.37 | ||||||

| 56 | 28.5 | 2 | 1.6 | 3.6 | 1910 | 3340 | 4440 | 5380 | 27.63 | ||||||

| 56 | 28.5 | 1.5 | 1.95 | 3.45 | 1460 | 2260 | 2620 | 2770 | 20.85 | ||||||

| 63 | 31 | 3.5 | 1.4 | 4.9 | 5400 | 10400 | 15000 | 19500 | 62.99 | ||||||

| 63 | 31 | 2 | 1.75 | 4.25 | 2940 | 5270 | 7190 | 8900 | 44.7 | ||||||

| 63 | 31 | 1.8 | 2.35 | 4.15 | 2360 | 3660 | 4240 | 4460 | 32.53 | ||||||

| 71 | 36 | 4 | 1.6 | 5.6 | 7380 | 14200 | 20500 | 26700 | 92.36 | ||||||

| 71 | 36 | 2.5 | 2 | 4.5 | 2890 | 5050 | 6730 | 8150 | 57.72 | ||||||

| 71 | 36 | 1.8 | 2.6 | 4.6 | 2860 | 4430 | 5140 | 5430 | 46.18 | ||||||

|

De h12 |

Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 80 | 41 | 5 | 1.7 | 6.7 | 11800 | 22900 | 33600 | 44000 | 145.468 | ||||||

| 80 | 41 | 2.5 | 2.3 | 5.3 | 4450 | 7840 | 10500 | 12800 | 87.281 | ||||||

| 80 | 41 | 2.25 | 2.95 | 5.2 | 3698 | 5715 | 6613 | 6950 | 65.460 | ||||||

| 90 | 46 | 5 | 2 | 7 | 11000 | 21600 | 31400 | 40800 | 184.463 | ||||||

| 90 | 46 | 3 | 2.5 | 6 | 5840 | 10400 | 14200 | 17500 | 129.124 | ||||||

| 90 | 46 | 2.5 | 3.2 | 5.7 | 4230 | 6580 | 7680 | 8160 | 92.231 | ||||||

| 100 | 51 | 6 | 2.2 | 8.2 | 17100 | 32900 | 48000 | 62700 | 273.698 | ||||||

| 100 | 51 | 3.5 | 2.8 | 6.3 | 5620 | 9820 | 13100 | 15800 | 159.657 | ||||||

| 100 | 51 | 2.7 | 6.5 | 6.2 | 4780 | 7410 | 8610 | 9090 | 123.164 | ||||||

| 112 | 57 | 6 | 2.5 | 8.5 | 15800 | 30200 | 43700 | 56700 | 343.833 | ||||||

| 112 | 57 | 4 | 3.2 | 7.2 | 7640 | 13300 | 17800 | 21500 | 229.222 | ||||||

| 112 | 57 | 3 | 3.9 | 6.9 | 5830 | 9040 | 10500 | 11100 | 171.917 | ||||||

| 125 | 64 | 8 | 2.6 | 10.6 | 30100 | 58600 | 85900 | 113000 | 529.900 | ||||||

| 125 | 64 | 5 | 3.5 | 8.5 | 12200 | 21900 | 29900 | 37000 | 426.471 | ||||||

| 125 | 64 | 3.5 | 4.5 | 8 | 8510 | 13200 | 15400 | 16300 | 248.775 | ||||||

| 140 | 72 | 8 | 3.2 | 11.2 | 30600 | 58800 | 85300 | 110000 | 666.581 | ||||||

| 140 | 72 | 5 | 4 | 9 | 12000 | 21000 | 27900 | 39800 | 444.388 | ||||||

| 140 | 72 | 3.8 | 4.9 | 8.7 | 9510 | 14800 | 17200 | 18200 | 337.734 | ||||||

| 160 | 82 | 10 | 3.5 | 13.5 | 48900 | 94600 | 138000 | 181000 | 1094.00 | ||||||

| 160 | 82 | 6 | 4.5 | 10.5 | 17200 | 30400 | 41000 | 50300 | 651.70 | ||||||

| 160 | 82 | 4.3 | 5.6 | 9.9 | 12200 | 18800 | 21800 | 23000 | 500.409 | ||||||

| 180 | 92 | 10 | 4 | 14 | 45100 | 86500 | 125000 | 163000 | 1387.00 | ||||||

| 180 | 92 | 6 | 5.1 | 11.1 | 16600 | 28600 | 37500 | 44900 | 826.39 | ||||||

| 180 | 92 | 4.8 | 6.2 | 11 | 14600 | 22700 | 26400 | 28000 | 708.337 | ||||||

| 200 | 102 | 12 | 4.2 | 16.2 | 64700 | 125000 | 183000 | 239000 | 2053.00 | ||||||

| 200 | 102 | 8 | 5.6 | 13.6 | 31300 | 56000 | 76400 | 94600 | 1368.00 | ||||||

| 200 | 102 | 5.5 | 7 | 12.5 | 19800 | 30900 | 36100 | 38400 | 1004.00 | ||||||

| 225 | 112 | 12 | 5 | 17 | 61800 | 118000 | 171000 | 222000 | 2641.00 | ||||||

| 225 | 112 | 8 | 6.5 | 14.5 | 30600 | 53300 | 70700 | 85500 | 1761.00 | ||||||

| 225 | 112 | 6.5 | 7.1 | 13.6 | 22300 | 36300 | 44600 | 50100 | 1455.00 | ||||||

| 250 | 127 | 14 | 5.6 | 19.6 | 89400 | 172000 | 249000 | 324000 | 3745.00 | ||||||

| 250 | 127 | 10 | 7 | 17 | 48700 | 87300 | 119000 | 147000 | 2687.00 | ||||||

| 250 | 127 | 7 | 7.8 | 14.8 | 25600 | 41300 | 50500 | 56400 | 1915.00 | ||||||

Full list of Suppliers of Disc springs

Tieig Industrial Group, founded in 1994, has more than 20 years experience in the production of Disc springs DIN 2093, Wedge-locking washers DIN 25201 and industrial adhesives.

Producer of shim adjustment ring also with chamfers.

Rings obtained from tapes.

Belleville washers, crinkle washers, wave spring washers.

Standardized and special elastic washers.

Special stampings and clamps

Manufacturer of retaining rings for shaftsand bores- Din 47; Din 472 mm and inches. Toothed washers.

Quality certificates: ISO/TS 16949-2009; ISO 9001-2008

Distributor specialized in circlips, disc springs,wave spring washers, roll pins and quick fixings

Biggest factory in China producing stainless steel washers.

Fat washers, spring washers, tooth lock washers and stamping parts.

Materials: 316L ,316S33,1.4462.

Manufacturer of standard and special washers in different materials, with internal diameter from 2.5 up to 80mm.

Manufacturer of disc springs, belleville washers, Rip lock washers and spring pins.

Manufacturer of finishing and cleaning plants for metal parts.

Distributor of retaining rings, Spiral retaining rings, wave springs, Disc springs, Washers, Elastic pins, Pins, Keys, Ground flat/bar stocks, Locking nuts, washers, Miniplast plastic parts, Metallic screws, nuts, bolts.

Manufacturer of all types of washers (flat, waved, square, toothed), turned parts and stampings

We focus on manufacturing disc springs, wave springs and serrated washers since 1984. Our facility is ISO9001:2008 Certified . Materies including 50CrV4, SUS301, SUS304, SUS316, 17- 4PH, 17-7PH, 15-7Mo,Inconel 718, Inconel 750, Nimonic 90, H13.

Manufacturer of washers, disc springs, wave spring washers, serrated safety washers, Belleville washers, serrated washers & lockrite washers.

Production and sales of disc springs, disc washers, waveform springs, diaphragm springs, special-shaped springs and other high-quality elastic components.

Fastener manufacturing company with more than 15 years experience.

Production range: all kinds of flat washers, spring washers, toothed washers, square washers, custom special washers.

Materials: stainless steel, carbon steel, brass.

Distributor of special washers, retaining rings, spring pins, slotted pins, spring cup washers

Manufacturer of flat washers standard and specials, UNC/SAE/STD, special washers and stampings

Distributor of disc spings, retaining rings, parallel keys and other fasteners, both standard and special following the specifications of the customents. We supply the right solution for any application.

Fast deliveries guaranteed, within 24/48 hours.

We offer our customers many services such as e-shop and online order management.

Manufacturer of retaining rings, starlock washers, toothed washers, slotted spring pins, quick fixings and special parts

Manufacturer, since 1985, of flat , assembly, elastic conical, and special washers and blanks. tranciata. Primary automotive automotive supplier

Quality certificates: ISO 9001-2000, TS 16949 2002.

Manufacturer of coil springs and distributor of disc springs, circlips,retaining rings, hose clamps, tool clips, retaining pins and linch pins, push on fasteners, shims and spring washers and split key rings.

Manufacturer specialized in all kinds of Plain Washers, Spring and wire washers, Circlips, Copper washers, Aluminum washers, Star washers, Conical star washers, Serrated washers, Conical washers, Spherical washers.

Manufacturer of flat washers, spring washers, toothed washers, contact washers, belleville washers, spring washers, retaining rings, stamping parts.

Manufacturer of retaining rings, special metallic fasteners, snap rings, spring pins, disc springs and speed nuts

Manufacturer of special washers and stampings in steel, stainless steel, alloy, copper, plastic

Manufacturer of circlips and pins. Retaining rings DIN 471, DIN 472, DIN 6799; Snap rings DIN 5417, SP series, RW/SW series, WRE snap rings, etc.. Disc springs DIN 2093, Spring pins DIN 1481 / ISO 8752