Lieferanten von Tellerfedern

Dieses Produkt unterliegt den folgenden Normen:

Technische Daten

Tellerfedern

Dieses Produkt unterliegt den folgenden Normen:

Standard UNI 8737

Tellerfedern

|

Dimensions in mm - UNI 8737 - Withdrawn Publication date: 11-1985 |

|||||||||

| De | Di | t | lo | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | |||||

| 8 | 4.2 | 0.2 | 0.45 | 0.05 | |||||

| 8 | 4.2 | 0.3 | 0.55 | 0.07 | |||||

| 8 | 4.2 | 0.4 | 0.6 | 0.1 | |||||

| 10 | 5.2 | 0.25 | 0.55 | 0.1 | |||||

| 10 | 5.2 | 0.4 | 0.7 | 0.16 | |||||

| 10 | 5.2 | 0.5 | 0.75 | 0.21 | |||||

| 12.5 | 6.2 | 0.35 | 0.8 | 0.23 | |||||

| 12.5 | 6.2 | 0.5 | 0.85 | 0.34 | |||||

| 12.5 | 6.2 | 0.7 | 1 | 0.47 | |||||

| 14 | 7.2 | 0.35 | 0.8 | 0.29 | |||||

| 14 | 7.2 | 0.5 | 0.9 | 0.42 | |||||

| 14 | 7.2 | 0.8 | 1.1 | 0.66 | |||||

| 16 | 8.2 | 0.4 | 0.9 | 0.44 | |||||

| 16 | 8.2 | 0.6 | 1.05 | 0.66 | |||||

| 16 | 8.2 | 0.9 | 1.25 | 0.99 | |||||

| 18 | 9.2 | 0.45 | 1.05 | 0.63 | |||||

| 18 | 9.2 | 0.7 | 1.2 | 0.98 | |||||

| 18 | 9.2 | 1 | 1.4 | 1.4 | |||||

| 20 | 10.2 | 0.5 | 1.15 | 0.87 | |||||

| 20 | 10.2 | 0.8 | 1.35 | 1.38 | |||||

| 20 | 10.2 | 1.1 | 1.55 | 1.91 | |||||

| 22.5 | 11.2 | 0.6 | 1.4 | 1.35 | |||||

| 22.5 | 11.2 | 0.8 | 1.45 | 1.79 | |||||

| 22.5 | 11.2 | 1.25 | 1.75 | 2.81 | |||||

| 25 | 12.2 | 0.7 | 1.6 | 1.96 | |||||

| 25 | 12.2 | 0.9 | 1.6 | 2.53 | |||||

| 25 | 12.2 | 1.5 | 2.05 | 4.24 | |||||

| 28 | 14.2 | 0.8 | 1.8 | 2.75 | |||||

| 28 | 14.2 | 1 | 1.8 | 3.45 | |||||

| 28 | 14.2 | 1.5 | 2.15 | 5.2 | |||||

| 31.5 | 16.3 | 0.8 | 1.85 | 3.4 | |||||

| 31.5 | 16.3 | 1.25 | 2.15 | 5.4 | |||||

| 31.5 | 16.3 | 1.75 | 2.45 | 7.6 | |||||

Standard DIN 2093

Tellerfedern

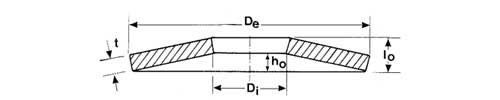

In dieser Norm (DIN 2093) sind alle Anforderungen zusammengestellt, die Tellerfedern erfüllen müssen, damit ihre Funktion sichergestellt ist. Es sind dies, neben den Anforderungen an Werkstoff und Fertigungsart, die Maß- und Krafttoleranzen, die Dauer- und Zeitfestigkeitsanforderungen sowie die Relaxationswerte bei statischer Beanspruchung. Tellerfedern sind konisch geformte Scheiben für axiale Belastung. Tellerfedern haben eine einzigartige Kombination aus hoher Festigkeit und personalisierbarer Ablenkung. sie bieten eine gut entwickelte Lösung für viele sektorspezifische Probleme. Tellerfedern können einzeln oder in Stapeln benuzt werden. Sie können in Reihe oder parallel gestapelt werden. Tellerfedern sind mit oder ohne Stützen verfügbar und werden nach DIN 2093 hergestellt und nach DIN 2092 entworfen.

|

Dimensions in mm - DIN 2093 - Withdrawn Publication date: 12/2013 - Supersedes DIN 2093 01/1992;

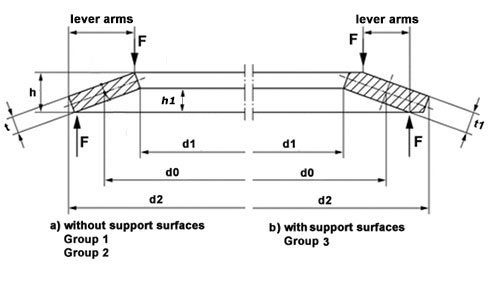

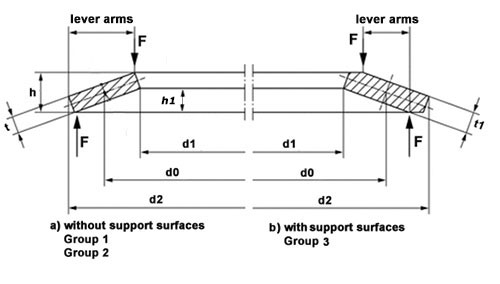

The DIN 2093 specification classifies disc springs into 3 groups: GROUP 1: under 1.25 mm thick (cold formed,radiused edges, without bearing flats) GROUP 2: 1.25 mm thick up to and including 6mm (cold formed,machined,radiused edges, without bearing flats) GROUP 3: above 6mm thick (fully machined from forged blanks, with bearing flats and thickness reduced) |

||||||||||||

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| - | 6 | 3.2 | 0.3 | 0.15 | 0.45 | - | 45 | 84 | 119 | 153 | 0.044 | |

| C | 8 | 4.2 | 0.2 | 0.25 | 0.45 | 21 | 33 | 39 | 42 | 0.055 | ||

| B | 8 | 4.2 | 0.3 | 0.25 | 0.55 | 1 | 52 | 89 | 118 | 142 | 0.08 | |

| A | 8 | 4.2 | 0.4 | 0.2 | 0.6 | 1 | 78 | 147 | 210 | 269 | 0.115 | |

| C | 10 | 5.2 | 0.25 | 0.3 | 0.55 | 1 | 30 | 48 | 58 | 63 | 0.109 | |

| B | 10 | 5.2 | 0.4 | 0.3 | 0.7 | 1 | 88 | 155 | 209 | 257 | 0.161 | |

| A | 10 | 5.2 | 0.5 | 0.25 | 0.75 | 1 | 122 | 228 | 325 | 418 | 0.209 | |

| C | 12.5 | 6.2 | 0.35 | 0.45 | 0.8 | 1 | 84 | 130 | 151 | 160 | 0.251 | |

| B | 12.5 | 6.2 | 0.5 | 0.35 | 0.85 | 1 | 120 | 215 | 293 | 363 | 0.251 | |

| A | 12.5 | 6.2 | 0.7 | 0.3 | 1 | 1 | 239 | 457 | 660 | 855 | 0.483 | |

| C | 14 | 7.2 | 0.35 | 0.45 | 0.8 | 1 | 68 | 106 | 123 | 131 | 0.308 | |

| B | 14 | 7.2 | 0.5 | 0.4 | 0.9 | 1 | 120 | 210 | 279 | 338 | 0.308 | |

| A | 14 | 7.2 | 0.8 | 0.3 | 1.1 | 1 | 284 | 547 | 797 | 1040 | 0.654 | |

| C | 16 | 8.2 | 0.4 | 0.55 | 0.9 | 1 | 84 | 131 | 154 | 165 | 0.444 | |

| B | 16 | 8.2 | 0.6 | 0.45 | 1.05 | 1 | 172 | 304 | 410 | 503 | 0.656 | |

| A | 16 | 8.2 | 0.9 | 0.45 | 1.25 | 1 | 363 | 697 | 1010 | 1320 | 0.994 | |

| C | 18 | 9.2 | 0.45 | 0.65 | 1.05 | 1 | 121 | 186 | 214 | 223 | 0.651 | |

| B | 18 | 9.2 | 0.7 | 0.6 | 1.2 | 1 | 233 | 417 | 586 | 699 | 1.05 | |

| A | 18 | 9.2 | 1 | 0.4 | 1.4 | 1 | 451 | 865 | 1250 | 1630 | 0.444 | |

| C | 20 | 10.2 | 0.5 | 0.65 | 1.15 | 1 | 141 | 219 | 254 | 268 | 0.876 | |

| B | 20 | 10.2 |

0.8 |

0.65 | 1.35 | 1 | 304 | 547 | 748 | 929 | 1.371 | |

| A | 20 | 10.2 | 1.1 |

0.45 |

1.55 | 1 | 548 | 1050 | 1520 | 1980 | 1.912 | |

| C | 22.5 | 11.2 | 0.6 | 0.8 | 1.4 | 1 | 240 | 370 | 425 | 444 | 1.361 | |

| B | 22.5 | 11.2 | 0.8 | 0.65 | 1.45 | 1 | 306 | 533 | 707 | 855 | 1.77 | |

| A | 22.5 | 11.2 | 1.25 | 0.5 | 1.75 | 1 | 693 |

1330 |

1930 | 2510 | 2.775 | |

| C | 25 | 12.2 | 0.7 | 0.9 | 1.6 | 1 | 331 | 515 | 600 | 635 | 1.984 | |

| B | 25 | 12.2 | 0.9 | 0.8 | 1.6 | 1 | 367 | 644 | 862 | 1050 | 2.5 | |

| A | 25 | 12.2 | 1.5 | 0.55 | 2.05 | 1 | 1040 | 2010 | 2930 | 3820 | 4.162 | |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| C | 28 | 14.2 | 0.8 | 1 | 1.8 | 1 | 435 | 681 | 801 | 859 | 2.76 | |

| B | 28 | 14.2 | 1 | 0.9 | 1.8 | 1 | 476 | 832 | 1110 | 1340 | 3.396 | |

| A | 28 | 14.2 | 1.5 | 0.65 | 2.15 | 2 | 1030 | 1970 | 2840 | 3680 | 5.107 | |

| C | 31.5 | 16.3 | 0.8 | 1.05 | 1.85 | 1 | 384 | 594 | 687 | 722 | 3.442 | |

| B | 31.5 | 16.3 | 1.25 | 1.15 | 2.15 | 2 | 791 | 1410 | 1910 | 2360 | 5.331 | |

| A | 31.5 | 16.3 | 1.75 | 0.7 | 2.45 | 2 | 1390 | 2670 | 3870 | 5040 | 7.493 | |

| C | 35.5 | 18.3 | 0.9 | 1.15 | 2.05 | 1 | 458 | 712 | 832 | 884 | 4.592 | |

| B | 35.5 | 18.3 | 1.25 | 1 | 2.25 | 2 | 731 | 1280 | 1700 | 2060 | 6.78 | |

| A | 35.5 | 18.3 | 2 | 0.8 | 2.8 | 2 | 1860 | 3580 | 5190 | 6750 | 11.03 | |

| C | 40 | 20.4 | 1 | 1.3 | 2.3 | 1 | 565 | 876 | 1020 | 1070 | 7.067 | |

| B | 40 | 20.4 | 1.5 | 1.4 | 2.65 | 2 | 1110 | 1950 | 2620 | 3290 | 10.392 | |

| A | 40 | 20.4 | 2.25 | 0.9 | 3.15 | 2 | 2340 | 4480 | 6500 | 8460 | 15.26 | |

| C | 45 | 22.4 | 1.25 | 1.6 | 2.85 | 2 | 1040 | 1620 | 1890 | 2100 | 15.95 | |

| B | 45 | 22.4 | 1.75 | 1.55 | 3.05 | 2 | 1520 | 2700 | 3650 | 4480 | 15.95 | |

| A | 45 | 22.4 | 2.5 | 1 | 3.5 | 2 | 2770 | 5320 | 7720 | 10000 | 22.313 | |

| C | 50 | 25.4 | 1.25 | 1.6 | 2.85 | 2 | 854 | 1330 | 1550 | 1650 | 13.82 | |

| B | 50 | 25.4 | 2 | 1.65 | 3.4 | 2 | 1950 | 3490 | 4760 | 5900 | 21.885 | |

| A | 50 | 25.4 | 3 | 1.1 | 4.1 | 2 | 4250 | 8210 | 12000 | 15600 | 32.529 | |

| C | 56 | 28.5 | 1.5 | 1.95 | 3.45 | 2 | 1460 | 2260 | 2620 | 2770 | 20.85 | |

| B | 56 | 28.5 | 2 | 1.6 | 3.6 | 2 | 1910 | 3340 | 4440 | 5380 | 27.63 | |

| A | 56 | 28.5 | 3 | 1.3 | 4.3 | 2 | 4140 | 7900 | 11400 | 14800 | 41.37 | |

| C | 63 | 31 | 1.8 | 2.35 | 4.15 | 2 | 2360 | 3660 | 4240 | 4460 | 32.53 | |

| B | 63 | 31 | 2.5 | 2.25 | 4.25 | 2 | 2940 | 5270 | 7190 | 8900 | 44.7 | |

| A | 63 | 31 | 3.5 | 1.4 | 4.9 | 2 | 5400 | 10400 | 15000 | 19500 | 62.99 | |

| C | 71 | 36 | 1 | 2.8 | 4.6 | 2 | 2860 | 4430 | 5140 | 5430 | 46.18 | |

| B | 71 | 36 | 2.5 | 2 | 4.5 | 2 | 2890 | 5050 | 6730 | 8150 | 57.72 | |

| A | 71 | 36 | 4 | 1.6 | 5.6 | 2 | 7380 | 14200 | 20500 | 26700 | 92.36 | |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) |

| C | 80 | 41 | 2.25 | 2.95 | 5.2 | 2 | 3698 | 5715 | 6613 | 6950 | 65.460 | |

| B | 80 | 41 | 3 | 2.8 | 5.3 | 2 | 4450 | 7840 | 10500 | 12800 | 87.281 | |

| A | 80 | 41 | 5 | 1.7 | 6.7 | 2 | 11800 | 22900 | 33600 | 44000 | 145.468 | |

| C | 90 | 46 | 2.5 | 3.2 | 5.7 | 2 | 4230 | 6580 | 7680 | 8160 | 92.231 | |

| B | 90 | 46 | 3.5 | 3 | 6 | 2 | 5840 | 10400 | 14200 | 17500 | 129.124 | |

| A | 90 | 46 | 5 | 2 | 7 | 2 | 11000 | 21600 | 31400 | 40800 | 184.463 | |

| C | 100 | 51 | 2.7 | 3.5 | 6.2 | 2 | 4780 | 7410 | 8610 | 9090 | 123.164 | |

| B | 100 | 51 | 3.5 | 2.8 | 6.3 | 2 | 5620 | 9820 | 13100 | 15800 | 159.657 | |

| A | 100 | 51 | 6 | 2.2 | 8.2 | 2 | 17100 | 32900 | 48000 | 62700 | 273.698 | |

| C | 112 | 57 | 3 | 3.9 | 6.9 | 2 | 5830 | 9040 | 10500 | 11100 | 171.917 | |

| B | 112 | 57 | 4 | 3.2 | 7.2 | 2 | 7640 | 13300 | 17800 | 21500 | 229.222 | |

| A | 112 | 57 | 6 | 2.5 | 8.5 | 2 | 15800 | 30200 | 43700 | 56700 | 343.833 | |

| C | 125 | 64 | 3.5 | 4.5 | 8 | 2 | 8510 | 13200 | 15400 | 16300 | 248.775 | |

| B | 125 | 64 | 5 | 3.5 | 8.5 | 2 | 12200 | 21900 | 29900 | 37000 | 426.471 | |

| A | 125 | 64 | 8 | 2.6 | 10.6 | 3 | 30100 | 58600 | 85900 | 113000 | 529.900 | |

| C | 140 | 72 | 3.8 | 4.9 | 8.7 | 2 | 9510 | 14800 | 17200 | 18200 | 337.734 | |

| B | 140 | 72 | 5 | 4 | 9 | 2 | 12000 | 21000 | 27900 | 39800 | 444.388 | |

| A | 140 | 72 | 8 | 3.2 | 11.2 | 3 | 30600 | 58800 | 85300 | 110000 | 666.581 | |

| C | 160 | 82 | 4.3 | 5.6 | 9.9 | 2 | 12200 | 18800 | 21800 | 23000 | 500.409 | |

| B | 160 | 82 | 6 | 4.5 | 10.5 | 2 | 17200 | 30400 | 41000 | 50300 | 651.70 | |

| A | 160 | 82 | 10 | 3.5 | 13.5 | 3 | 48900 | 94600 | 138000 | 181000 | 1094.00 | |

| C | 180 | 92 | 4.8 | 6.2 | 11 | 2 | 14600 | 22700 | 26400 | 28000 | 708.337 | |

| B | 180 | 92 | 6 | 5.1 | 11.1 | 2 | 16600 | 28600 | 37500 | 44900 | 826.39 | |

| A | 180 | 92 | 10 | 4 | 14 | 3 | 45100 | 86500 | 125000 | 163000 | 1387.00 | |

| C | 200 | 102 | 5.5 | 7 | 12.5 | 2 | 19800 | 30900 | 36100 | 38400 | 1004.00 | |

| B | 200 | 102 | 8 | 5.6 | 13.6 | 3 | 31300 | 56000 | 76400 | 94600 | 1368.00 | |

| A | 200 | 102 | 12 | 4.2 | 16.2 | 3 | 64700 | 125000 | 183000 | 239000 | 2053.00 | |

| C | 225 | 112 | 6.5 | 7.1 | 13.6 | 3 | 22300 | 36300 | 44600 | 50100 | 1455.00 | |

| B | 225 | 112 | 8 | 6.5 | 14.5 | 3 | 30600 | 53300 | 70700 | 85500 | 1761.00 | |

| A | 225 | 112 | 12 | 5 | 17 | 3 | 61800 | 118000 | 171000 | 222000 | 2641.00 | |

| C | 250 | 127 | 7 | 7.8 | 14.8 | 3 | 25600 | 41300 | 50500 | 56400 | 1915.00 | |

| B | 250 | 127 | 10 | 7 | 17 | 3 | 48700 | 87300 | 119000 | 147000 | 2687.00 | |

| A | 250 | 127 | 14 | 5.6 | 19.6 | 3 | 89400 | 172000 | 249000 | 324000 | 3745.00 | |

Standard DIN EN 16983

Tellerfedern

|

Dimensions in mm - DIN EN 16983 Publication date: 09/2017

The DIN EN 16983 specification classifies disc springs into 3 groups: GROUP 1: under 1.25 mm thick (cold formed,radiused edges, iwthout bearing flats) GROUP 2: 1.25 mm thickup to and including 6mm (cold formed,machined,radiused edges, iwthout bearing flats) GROUP 3: above 6mm thick (fully machined from forged blanks, with bearing flats and thickness reduced) |

|||||||

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| - | 6 | 3.2 | 0.3 | - | 0.15 | 0.45 | - |

| C | 8 | 4.2 | 0.2 | - | 0.25 | 0.45 | |

| B | 8 | 4.2 | 0.3 | - | 0.25 | 0.55 | 1 |

| A | 8 | 4.2 | 0.4 | - | 0.2 | 0.6 | 1 |

| C | 10 | 5.2 | 0.25 | - | 0.3 | 0.55 | 1 |

| B | 10 | 5.2 | 0.4 | - | 0.3 | 0.7 | 1 |

| A | 10 | 5.2 | 0.5 | - | 0.25 | 0.75 | 1 |

| C | 12.5 | 6.2 | 0.35 | - | 0.45 | 0.8 | 1 |

| B | 12.5 | 6.2 | 0.5 | - | 0.35 | 0.85 | 1 |

| A | 12.5 | 6.2 | 0.7 | - | 0.3 | 1 | 1 |

| C | 14 | 7.2 | 0.35 | - | 0.45 | 0.8 | 1 |

| B | 14 | 7.2 | 0.5 | - | 0.4 | 0.9 | 1 |

| A | 14 | 7.2 | 0.8 | - | 0.3 | 1.1 | 1 |

| C | 16 | 8.2 | 0.4 | - | 0.55 | 0.9 | 1 |

| B | 16 | 8.2 | 0.6 | - | 0.45 | 1.05 | 1 |

| A | 16 | 8.2 | 0.9 | - | 0.45 | 1.25 | 1 |

| C | 18 | 9.2 | 0.45 | - | 0.65 | 1.05 | 1 |

| B | 18 | 9.2 | 0.7 | - | 0.6 | 1.2 | 1 |

| A | 18 | 9.2 | 1 | - | 0.4 | 1.4 | 1 |

| C | 20 | 10.2 | 0.5 | - | 0.65 | 1.15 | 1 |

| B | 20 | 10.2 |

0.8 |

- | 0.65 | 1.35 | 1 |

| A | 20 | 10.2 | 1.1 | - |

0.45 |

1.55 | 1 |

| C | 22.5 | 11.2 | 0.6 | - | 0.8 | 1.4 | 1 |

| B | 22.5 | 11.2 | 0.8 | - | 0.65 | 1.45 | 1 |

| A | 22.5 | 11.2 | 1.25 | - | 0.5 | 1.75 | 1 |

| C | 25 | 12.2 | 0.7 | - | 0.9 | 1.6 | 1 |

| B | 25 | 12.2 | 0.9 | - | 0.8 | 1.6 | 1 |

| A | 25 | 12.2 | 1.5 | - | 0.55 | 2.05 | 1 |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| C | 28 | 14.2 | 0.8 | - | 1 | 1.8 | 1 |

| B | 28 | 14.2 | 1 | - | 0.9 | 1.8 | 1 |

| A | 28 | 14.2 | 1.5 | - | 0.65 | 2.15 | 2 |

| C | 31.5 | 16.3 | 0.8 | - | 1.05 | 1.85 | 1 |

| B | 31.5 | 16.3 | 1.25 | - | 1.15 | 2.15 | 2 |

| A | 31.5 | 16.3 | 1.75 | - | 0.7 | 2.45 | 2 |

| C | 35.5 | 18.3 | 0.9 | - | 1.15 | 2.05 | 1 |

| B | 35.5 | 18.3 | 1.25 | - | 1 | 2.25 | 2 |

| A | 35.5 | 18.3 | 2 | - | 0.8 | 2.8 | 2 |

| C | 40 | 20.4 | 1 | - | 1.3 | 2.3 | 1 |

| B | 40 | 20.4 | 1.5 | - | 1.4 | 2.65 | 2 |

| A | 40 | 20.4 | 2.25 | - | 0.9 | 3.15 | 2 |

| C | 45 | 22.4 | 1.25 | - | 1.6 | 2.85 | 2 |

| B | 45 | 22.4 | 1.75 | - | 1.55 | 3.05 | 2 |

| A | 45 | 22.4 | 2.5 | - | 1 | 3.5 | 2 |

| C | 50 | 25.4 | 1.25 | - | 1.6 | 2.85 | 2 |

| B | 50 | 25.4 | 2 | - | 1.65 | 3.4 | 2 |

| A | 50 | 25.4 | 3 | - | 1.1 | 4.1 | 2 |

| C | 56 | 28.5 | 1.5 | - | 1.95 | 3.45 | 2 |

| B | 56 | 28.5 | 2 | - | 1.6 | 3.6 | 2 |

| A | 56 | 28.5 | 3 | - | 1.3 | 4.3 | 2 |

| C | 63 | 31 | 1.8 | - | 2.35 | 4.15 | 2 |

| B | 63 | 31 | 2.5 | - | 2.25 | 4.25 | 2 |

| A | 63 | 31 | 3.5 | - | 1.4 | 4.9 | 2 |

| C | 71 | 36 | 1 | - | 2.8 | 4.6 | 2 |

| B | 71 | 36 | 2.5 | - | 2 | 4.5 | 2 |

| A | 71 | 36 | 4 | - | 1.6 | 5.6 | 2 |

| Type | d2 max=nom size (h12) | d1 min= nom size (H12) | t thickness | t1 | h1 cone height | h overall height | group |

| C | 80 | 41 | 2.25 | - | 2.95 | 5.2 | 2 |

| B | 80 | 41 | 3 | - | 2.8 | 5.3 | 2 |

| A | 80 | 41 | 5 | - | 1.7 | 6.7 | 2 |

| C | 90 | 46 | 2.5 | - | 3.2 | 5.7 | 2 |

| B | 90 | 46 | 3.5 | - | 3 | 6 | 2 |

| A | 90 | 46 | 5 | - | 2 | 7 | 2 |

| C | 100 | 51 | 2.7 | - | 3.5 | 6.2 | 2 |

| B | 100 | 51 | 3.5 | - | 2.8 | 6.3 | 2 |

| A | 100 | 51 | 6 | - | 2.2 | 8.2 | 2 |

| C | 112 | 57 | 3 | - | 3.9 | 6.9 | 2 |

| B | 112 | 57 | 4 | - | 3.2 | 7.2 | 2 |

| A | 112 | 57 | 6 | - | 2.5 | 8.5 | 2 |

| C | 125 | 64 | 3.5 | - | 4.5 | 8 | 2 |

| B | 125 | 64 | 5 | - | 3.5 | 8.5 | 2 |

| A | 125 | 64 | 8 | 7.5 | 2.6 | 10.6 | 3 |

| C | 140 | 72 | 3.8 | - | 4.9 | 8.7 | 2 |

| B | 140 | 72 | 5 | - | 4 | 9 | 2 |

| A | 140 | 72 | 8 | 7.5 | 3.2 | 11.2 | 3 |

| C | 160 | 82 | 4.3 | - | 5.6 | 9.9 | 2 |

| B | 160 | 82 | 6 | - | 4.5 | 10.5 | 2 |

| A | 160 | 82 | 10 | 9.4 | 3.5 | 13.5 | 3 |

| C | 180 | 92 | 4.8 | - | 6.2 | 11 | 2 |

| B | 180 | 92 | 6 | - | 5.1 | 11.1 | 2 |

| A | 180 | 92 | 10 | 9.4 | 4 | 14 | 3 |

| C | 200 | 102 | 5.5 | - | 7 | 12.5 | 2 |

| B | 200 | 102 | 8 | 7.5 | 5.6 | 13.6 | 3 |

| A | 200 | 102 | 12 | 11.25 | 4.2 | 16.2 | 3 |

| C | 225 | 112 | 6.5 | 6.2 | 7.1 | 13.6 | 3 |

| B | 225 | 112 | 8 | 7.5 | 6.5 | 14.5 | 3 |

| A | 225 | 112 | 12 | 11.25 | 5 | 17 | 3 |

| C | 250 | 127 | 7 | 6.7 | 7.8 | 14.8 | 3 |

| B | 250 | 127 | 10 | 9.4 | 7 | 17 | 3 |

| A | 250 | 127 | 14 | 13.1 | 5.6 | 19.6 | 3 |

Standard UNI 8736

Standard DIN EN 16984

Tellerfedern - Berechnung

Daten

Tellerfedern

|

Dimensions in mm - DIN 2093 - Withdrawn Material: spring steel Publication date: 12/2013 - Supersedes DIN 2093 01/1992 |

|||||||||||||||

| De h12 | Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 6 | 3.2 | 0.3 | 0.15 | 0.45 | 45 | 84 | 119 | 153 | 0.044 | ||||||

| 8 | 4.2 | 0.4 | 0.2 | 0.6 | 78 | 147 | 210 | 269 | 0.115 | ||||||

| 8 | 4.2 | 0.3 | 0.25 | 0.55 | 52 | 89 | 118 | 142 | 0.08 | ||||||

| 8 | 4.2 | 0.2 | 0.25 | 0.45 | 21 | 33 | 39 | 42 | 0.055 | ||||||

| 10 | 5.2 | 0.5 | 0.25 | 0.75 | 122 | 228 | 325 | 418 | 0.209 | ||||||

| 10 | 5.2 | 0.4 | 0.3 | 0.7 | 88 | 155 | 209 | 257 | 0.161 | ||||||

| 10 | 5.2 | 0.25 | 0.3 | 0.55 | 30 | 48 | 58 | 63 | 0.109 | ||||||

| 12.5 | 6.2 | 0.7 | 0.3 | 1 | 239 | 457 | 660 | 855 | 0.483 | ||||||

| 12.5 | 6.2 | 0.5 | 0.35 | 0.85 | 120 | 215 | 293 | 363 | 0.251 | ||||||

| 12.5 | 6.2 | 0.35 | 0.45 | 0.8 | 84 | 130 | 151 | 160 | 0.251 | ||||||

| 14 | 7.2 | 0.8 | 0.3 | 1.1 | 284 | 547 | 797 | 1040 | 0.654 | ||||||

| 14 | 7.2 | 0.5 | 0.4 | 0.9 | 120 | 210 | 279 | 338 | 0.308 | ||||||

| 14 | 7.2 | 0.35 | 0.45 | 0.8 | 68 | 106 | 123 | 131 | 0.308 | ||||||

| 16 | 8.2 | 0.8 | 0.35 | 1.25 | 363 | 697 | 1010 | 1320 | 0.994 | ||||||

| 16 | 8.2 | 0.6 | 0.45 | 1.05 | 172 | 304 | 410 | 503 | 0.656 | ||||||

| 16 | 8.2 | 0.35 | 0.4 | 0.9 | 84 | 131 | 154 | 165 | 0.444 | ||||||

| 18 | 9.2 | 1 | 0.4 | 1.4 | 451 | 865 | 1250 | 1630 | 0.444 | ||||||

| 18 | 9.2 | 0.6 | 1.2 | 1.2 | 233 | 417 | 586 | 699 | 1.05 | ||||||

| 18 | 9.2 | 0.4 | 1.05 | 1.05 | 121 | 186 | 214 | 223 | 0.651 | ||||||

| 20 | 10.2 | 1.1 |

0.45 |

1.55 | 548 | 1050 | 1520 | 1980 | 1.912 | ||||||

| 20 | 10.2 | 0.7 | 1.35 | 1.35 | 304 | 547 | 748 | 929 | 1.371 | ||||||

| 20 | 10.2 | 0.5 | 1.15 | 1.15 | 141 | 219 | 254 | 268 | 0.876 | ||||||

| 22.5 | 11.2 | 1.25 | 1.75 | 1.75 | 693 |

1330 |

1930 | 2510 | 2.775 | ||||||

| 22.5 | 11.2 | 0.8 | 1.45 | 1.45 | 306 | 533 | 707 | 855 | 1.77 | ||||||

| 22.5 | 11.2 | 0.6 | 1.4 | 1.4 | 240 | 370 | 425 | 444 | 1.361 | ||||||

| 25 | 12.2 | 1.5 | 2.05 | 2.05 | 1040 | 2010 | 2930 | 3820 | 4.162 | ||||||

| 25 | 12.2 | 0.8 | 1.6 | 1.6 | 367 | 644 | 862 | 1050 | 2.5 | ||||||

| 25 | 12.2 | 0.7 | 1.6 | 1.6 | 331 | 515 | 600 | 635 | 1.984 | ||||||

| De h12 | Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 28 | 14.2 | 1.5 | 0.65 | 2.15 | 1030 | 1970 | 2840 | 3680 | 5.107 | ||||||

| 28 | 14.2 | 0.9 | 0.8 | 1.8 | 476 | 832 | 1110 | 1340 | 3.396 | ||||||

| 28 | 14.2 | 0.8 | 1 | 1.8 | 435 | 681 | 801 | 859 | 2.76 | ||||||

| 31.5 | 16.3 | 1.75 | 0.7 | 2.45 | 1390 | 2670 | 3870 | 5040 | 7.493 | ||||||

| 31.5 | 16.3 | 1 | 0.9 | 2.15 | 791 | 1410 | 1910 | 2360 | 5.331 | ||||||

| 31.5 | 16.3 | 0.8 | 1.05 | 1.85 | 384 | 594 | 687 | 722 | 3.442 | ||||||

| 35.5 | 18.3 | 2 | 0.8 | 2.8 | 1860 | 3580 | 5190 | 6750 | 11.03 | ||||||

| 35.5 | 18.3 | 1.25 | 1 | 2.25 | 731 | 1280 | 1700 | 2060 | 6.78 | ||||||

| 35.5 | 18.3 | 0.9 | 1.15 | 2.05 | 458 | 712 | 832 | 884 | 4.592 | ||||||

| 40 | 20.4 | 2.25 | 0.9 | 3.15 | 2340 | 4480 | 6500 | 8460 | 15.26 | ||||||

| 40 | 20.4 | 1.25 | 1.15 | 2.65 | 1110 | 1950 | 2620 | 3290 | 10.392 | ||||||

| 40 | 20.4 | 1 | 1.3 | 2.3 | 565 | 876 | 1020 | 1070 | 7.067 | ||||||

| 45 | 22.4 | 2.5 | 1 | 3.5 | 2770 | 5320 | 7720 | 10000 | 22.313 | ||||||

| 45 | 22.4 | 1.5 | 1.3 | 3.05 | 1520 | 2700 | 3650 | 4480 | 15.95 | ||||||

| 45 | 22.4 | 1.25 | 1.6 | 2.85 | 1040 | 1620 | 1890 | 2100 | 15.95 | ||||||

| 50 | 25.4 | 3 | 1.1 | 4.1 | 4250 | 8210 | 12000 | 15600 | 32.529 | ||||||

| 50 | 25.4 | 1.75 | 1.4 | 3.4 | 1950 | 3490 | 4760 | 5900 | 21.885 | ||||||

| 50 | 25.4 | 1.25 | 1.6 | 2.85 | 854 | 1330 | 1550 | 1650 | 13.82 | ||||||

| 56 | 28.5 | 3 | 1.3 | 4.3 | 4140 | 7900 | 11400 | 14800 | 41.37 | ||||||

| 56 | 28.5 | 2 | 1.6 | 3.6 | 1910 | 3340 | 4440 | 5380 | 27.63 | ||||||

| 56 | 28.5 | 1.5 | 1.95 | 3.45 | 1460 | 2260 | 2620 | 2770 | 20.85 | ||||||

| 63 | 31 | 3.5 | 1.4 | 4.9 | 5400 | 10400 | 15000 | 19500 | 62.99 | ||||||

| 63 | 31 | 2 | 1.75 | 4.25 | 2940 | 5270 | 7190 | 8900 | 44.7 | ||||||

| 63 | 31 | 1.8 | 2.35 | 4.15 | 2360 | 3660 | 4240 | 4460 | 32.53 | ||||||

| 71 | 36 | 4 | 1.6 | 5.6 | 7380 | 14200 | 20500 | 26700 | 92.36 | ||||||

| 71 | 36 | 2.5 | 2 | 4.5 | 2890 | 5050 | 6730 | 8150 | 57.72 | ||||||

| 71 | 36 | 1.8 | 2.6 | 4.6 | 2860 | 4430 | 5140 | 5430 | 46.18 | ||||||

|

De h12 |

Di H12 | t | Ho | lo | F (0.25Ho) N | F (0.50Ho) N |

F (0.75Ho) N |

F (0.100Ho) N | weight in Kg x 1000 pcs (ρ=7.85 kg/dm3) | ||||||

| 80 | 41 | 5 | 1.7 | 6.7 | 11800 | 22900 | 33600 | 44000 | 145.468 | ||||||

| 80 | 41 | 2.5 | 2.3 | 5.3 | 4450 | 7840 | 10500 | 12800 | 87.281 | ||||||

| 80 | 41 | 2.25 | 2.95 | 5.2 | 3698 | 5715 | 6613 | 6950 | 65.460 | ||||||

| 90 | 46 | 5 | 2 | 7 | 11000 | 21600 | 31400 | 40800 | 184.463 | ||||||

| 90 | 46 | 3 | 2.5 | 6 | 5840 | 10400 | 14200 | 17500 | 129.124 | ||||||

| 90 | 46 | 2.5 | 3.2 | 5.7 | 4230 | 6580 | 7680 | 8160 | 92.231 | ||||||

| 100 | 51 | 6 | 2.2 | 8.2 | 17100 | 32900 | 48000 | 62700 | 273.698 | ||||||

| 100 | 51 | 3.5 | 2.8 | 6.3 | 5620 | 9820 | 13100 | 15800 | 159.657 | ||||||

| 100 | 51 | 2.7 | 6.5 | 6.2 | 4780 | 7410 | 8610 | 9090 | 123.164 | ||||||

| 112 | 57 | 6 | 2.5 | 8.5 | 15800 | 30200 | 43700 | 56700 | 343.833 | ||||||

| 112 | 57 | 4 | 3.2 | 7.2 | 7640 | 13300 | 17800 | 21500 | 229.222 | ||||||

| 112 | 57 | 3 | 3.9 | 6.9 | 5830 | 9040 | 10500 | 11100 | 171.917 | ||||||

| 125 | 64 | 8 | 2.6 | 10.6 | 30100 | 58600 | 85900 | 113000 | 529.900 | ||||||

| 125 | 64 | 5 | 3.5 | 8.5 | 12200 | 21900 | 29900 | 37000 | 426.471 | ||||||

| 125 | 64 | 3.5 | 4.5 | 8 | 8510 | 13200 | 15400 | 16300 | 248.775 | ||||||

| 140 | 72 | 8 | 3.2 | 11.2 | 30600 | 58800 | 85300 | 110000 | 666.581 | ||||||

| 140 | 72 | 5 | 4 | 9 | 12000 | 21000 | 27900 | 39800 | 444.388 | ||||||

| 140 | 72 | 3.8 | 4.9 | 8.7 | 9510 | 14800 | 17200 | 18200 | 337.734 | ||||||

| 160 | 82 | 10 | 3.5 | 13.5 | 48900 | 94600 | 138000 | 181000 | 1094.00 | ||||||

| 160 | 82 | 6 | 4.5 | 10.5 | 17200 | 30400 | 41000 | 50300 | 651.70 | ||||||

| 160 | 82 | 4.3 | 5.6 | 9.9 | 12200 | 18800 | 21800 | 23000 | 500.409 | ||||||

| 180 | 92 | 10 | 4 | 14 | 45100 | 86500 | 125000 | 163000 | 1387.00 | ||||||

| 180 | 92 | 6 | 5.1 | 11.1 | 16600 | 28600 | 37500 | 44900 | 826.39 | ||||||

| 180 | 92 | 4.8 | 6.2 | 11 | 14600 | 22700 | 26400 | 28000 | 708.337 | ||||||

| 200 | 102 | 12 | 4.2 | 16.2 | 64700 | 125000 | 183000 | 239000 | 2053.00 | ||||||

| 200 | 102 | 8 | 5.6 | 13.6 | 31300 | 56000 | 76400 | 94600 | 1368.00 | ||||||

| 200 | 102 | 5.5 | 7 | 12.5 | 19800 | 30900 | 36100 | 38400 | 1004.00 | ||||||

| 225 | 112 | 12 | 5 | 17 | 61800 | 118000 | 171000 | 222000 | 2641.00 | ||||||

| 225 | 112 | 8 | 6.5 | 14.5 | 30600 | 53300 | 70700 | 85500 | 1761.00 | ||||||

| 225 | 112 | 6.5 | 7.1 | 13.6 | 22300 | 36300 | 44600 | 50100 | 1455.00 | ||||||

| 250 | 127 | 14 | 5.6 | 19.6 | 89400 | 172000 | 249000 | 324000 | 3745.00 | ||||||

| 250 | 127 | 10 | 7 | 17 | 48700 | 87300 | 119000 | 147000 | 2687.00 | ||||||

| 250 | 127 | 7 | 7.8 | 14.8 | 25600 | 41300 | 50500 | 56400 | 1915.00 | ||||||

Vollständige Liste von Anbietern von Tellerfedern

Tieig Industrial Group, gegründet im Jahre 1994, verfügt über mehr als 20 Jahre Erfahrung in der Herstellung von Tellerfedern DIN 2093, Keilsicherungsscheiben DIN 25201 und Industrieklebstoffen.

Hersteller von Passcheiben,

Tellerfedern, gewellten Scheiben, Federscheiben.

Schellen und Federschellen

Hersteller von Sicherungsringen für Wellen und Ausbohrungen; Din 471-Din 472. Zahnscheiben

Qualitätszertifikate: ISO/TS 16949-2009; ISO 9001-2008

Größster Hersteller in China von Scheiben aus Edelstahl.

Flache-, Feder-, verzahnte Scheiben und Stanzteile.

Materiali: 316L ,316S33,1.4462.

Hersteller von Federn, Stanzbiegeteilen, Toleranzringen, Spannband, Drehstäbe, Endlosspiralen, Förderwendeln, Ringen, Drall-Fix

Hersteller von Standard- und Sonderscheiben aus verschiedenen Materialien, mit Innendurchmessern von 2.5 bis 80mm.

Hersteller von Tellerfedern, Keilsicherungsscheiben und Spannstiften.

Veredelungs- und Reinigungsanlagen für Metallteile.

Verteiler von retaining rings, Spiral retaining rings, wave springs, Disc springs, Washers, Elastic pins, Pins, Keys, Ground flat/bar stocks, Locking nuts, washers, Miniplast plastic parts, Metallic screws, nuts, bolts.

Hersteller von allen Scheiben-Typen (flache, wellige, viereckige, ausgezahnte), Dreh- und Stanzteile

Unser Fokus liegt seit 1984 in der Herstellung von Tellerfedern, gewellte Scheiben und Zahnscheiben. Unsere Produktionsstätte ist nach ISO9001:2008 zertifiziert. Die verwendeten Materialien schließen 50CrV4, SUS301, SUS304, SUS316, 17-4PH, 17-7PH, 15-7Mo, Inconel 718, Inconel 750, Nimonic 90, H13 ein.

Herstellung und Verkauf von Becherfedern, Wellfederscheiben, Membranscheiben, Spezialfederscheiben und anderen hochwertigen elastischen Bauteilen.

Hersteller von Sicherungsringe, Sprengringe, Scheiben, Scheibenfedern, Federstifte, Schlüssel.

Hersteller von Fasteners mit über 15 Jahren Erfahrung.

Produktpalette: flache Scheiben in allen Ausführungen, Federscheiben, Zahnscheiben, Vierktanscheiben, Sonderscheiben nach Zeichnung.

Materialien: Edelstahl, Karbonstahl, Messing.

Händler von Scheiben nach Zeichnung, Sicherungsringen, Spnannstiften, Tellerfedern und Kerbstiften

Verteiler von Tellerfedern, Sicherungsringen, Federkeilen und anderen Standardverbindungselementen und Sonderteilen nach Zeichnung oder Kundenangabe. Wir bieten die richtige Lösung für die angegebene Anwendung.

Wir garantieren schnelle Lieferungen innerhalb 24/48 Stunden.

Wir bieten unseren Kunden viele Dienstleistungen, wie E-Shop und Online-Auftragsverwaltung.

Hersteller von Sicherungsringen, Starloc-Scheiben, Zahnscheiben, Spannstiften, Schnellbefestigungen und Sonderteilen

Hersteller seit 1985 von Flache- Sonder- und Montagescheiben. Elastische- und Konische Scheiben. Unterlegscheiben und Stanzteile. Führender Händler für die Automobilindustrie

Qualitätszertifikate: ISO 9001-2000, TS 16949 2002.

Qualitätszertifikate: ISO 9001-2000, TS 16949 2002.

Hersteller von Federn und Verteiler von Tellerfedern, Ringen, Schlauchschellen, Klappsteckern

Hersteller spezialisiert auf alle Arten von flachen Scheiben, Federscheiben, Ringen, Scheiben aus Messing und Aluminium, Zahnscheiben, konische Scheiben und Kugelscheiben

Hersteller von Unterlegscheiben, Federscheiben, Zahnscheiben, Sperrkantscheiben, Spannscheiben, Sicherungsringe, Stanzteile. Metrische- und Zollabmessungen.

Hersteller von Sicherungsringen, Spannstiften, Tellerfedern, schnellen Metallbefestigungen

Hersteller von Ringen und Scheiben wie Sicherungsringe und Scheiben DIN 471, DIN 472, DIN 6799, Sprengringe DIN 5417, Sprengringe Serie SP, Serie RW/SW und WRE. Tellerfedern DIN 2093, Spannstifte DIN 1481 / ISO 8752